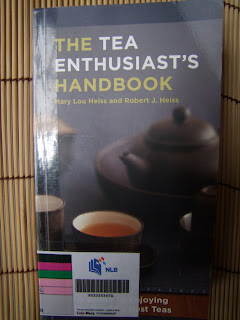

Printed this year by Crown Publishing, 'The Tea Enthusiast's Handbook' is written by Mary Lou Heiss and Robert J. Heiss. A look at the the back of the book (click pix for enlarged views) revealed that the authors are also tea retailers for their shop 'Tea Trekker' in the States.

I found the book very informative and the many photo illustrations make this book an extremely readable one. I found, that the authors took many pictures of the various teas and also the various colors of these tea brews, which makes the reading very pleasant and it was easy to relate and understand the tea information presented by the authors.

The book deals with purchasing tea, steeping the perfect cup and the 6 classes of tea (green, yellow, white, oolong, black and pu erh tea). The authors, in their selection of teas, do provide detailed information of each type of tea and recommend the steeping times for brewing these teas.

The authors also provided some interesting information on pu erh tea which is as follows;

"We had the opportunity to visit the Xiaguan Tea Factory, which is famous for their tuo-cha(nest-shaped) Pu-erh, the very tea we observed in production. The maocha is blended by the workers before they pack it into the perforated mold that will shape the tuo-cha. Two workers sat with two bags of mao cha in front of them, and they put some leaf from each bag into the mold in such a way that the smaller leaves were tucked inside the tuo-cha and the larger, more attractive leaves were visible on the surface.......

Shou Pu-erh is made in tea factories using the wo dui process. Wo dui begins by spreading the mao cha in a deep pile on the factory floor, and the leaf is dampened with mists of water. After the proper dampening, a thermal blanket is put over the pile of leaf. Heat builds up in the pile, encouraging both oxidation of the leaf and fermentation as enzymatic changes start to occcur within the leaf. This heat buildup encourages the viability of the natural bacteria present on the leaf, stimulating and initiating the fermentation process. The pile is turned every day or so a to allow each leaf to spend some time in different layers of the pile. When we visited the Menghai Tea factory, we were told that their wo dui process takes sixty to seventy days to complete. After wo dui is completed, the leaf is dried to a moisture level of approximately 10 percent.

After this stage, the leaf is compressed and shaped in a hydraulic machine. The tea cakes are then put in a drying room where they will rest and continue to dry on racks before being wrapped."

A reading of the above passages seem to suggest the following:

a) it is a normal practice for a tea cake to have nicer or bigger leaves on the outside of the cake and have the 'not so nice' leaves on the inside of the cake. My discovery of this phenomena was highlighted in my 13 nov'09 blog when I found out that the leaves inside a 2000 ripe brick looked different from the leaves that were on the surface of the brick. I suppose it makes economic and marketing sense......in that you can't expect perfect leaves in every production. Sure you will get tea leaves of different sizes not to mention some broken or torn leaves. My recommendation is that you break up a cake totally and and place the pieces in a tea caddy, That way, a brewing of this tea will be more representative of the tea than just peeling bits and pieces of the cake.

b) the authors seem to suggest that the fermentation of ripe pu erh is natural in that the tea factories do not add any enzymes or fermenting bacteria into the fermentation process. Ripe puerh achieved a super fast fermentation process than raw pu erh due to to the added moisture and heat(thermal blankets).

I enjoy reading "The Tea Enthusiast's Handbook".

No comments:

Post a Comment